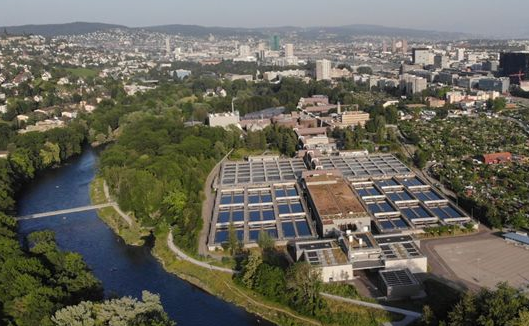

The largest sewage plant in Switzerland: Werdhoelzli (Werdhoelzli) sewage treatment plant is the world's largest sewage treatment plant for the removal of micro-pollutants. It has unique ozone removal microorganisms and sludge heat treatment technology.

The whole picture of the sewage plant

( 1 ) Process flow (“five stages” advanced treatment)

Wastewater from entering the Wade Hordsley WWTP will undergo a five-stage advanced treatment process: mechanical, biological, chemical, ozonation and filtration.

1. Mechanical treatment stage

The mechanical treatment process includes pretreatment and sedimentation tanks.

The pretreatment process is mainly to remove insoluble pollutants in wastewater. Some larger pollutants such as textiles, paper and wood will be caught by the screen; stones and metal pieces will settle at the bottom of the bunker.

Wastewater after removal of large-particle pollutants flows into sedimentation tanks where insoluble pollutants, such as food scraps and feces, settle and form sludge. At the same time, grease and oil also float on the water surface and are scraped off by constantly blowing air in.

2. Biological treatment stage

Here, microorganisms (activated sludge) further purify the wastewater. Microorganisms break down most organically dissolved pollutants.

By switching the tanks, switching between aerobic and anaerobic phases is achieved, converting ammonium salts into nitrates, which are then converted into gaseous nitrogen.

3. Chemical treatment stage

This process takes place concurrently with biological cleaning. The main purpose is to remove phosphate from detergents, cleaners and food in wastewater.

Therefore, when iron salts are added to wastewater, the insoluble compounds formed will flocculate with activated sludge and settle to the bottom of the clarifier, and return to the biofilter through the scraper arm.

The excess sludge is sent to the sludge digestion system together with the sludge from the mechanical treatment process.

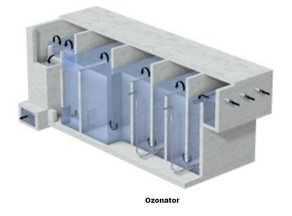

4. Ozone oxidation stage

The system was only introduced in 2016 to provide ozone to Wade Hordsley Sewage Works (the system is capable of producing 153kg of ozone per hour to handle a flow of 6500 liters per second).

The principle of the device is to use artificial lightning to generate ozone from oxygen. The main source of oxygen is the surrounding air, which is decomposed into oxygen and nitrogen by vacuum pressure swing adsorption.

Gaseous ozone in wastewater decomposes trace pollutants such as drug residues, pesticides or hormones. (The technology is currently capable of removing 80 percent of trace pollutants in wastewater without producing harmful chlorinated by-products.)

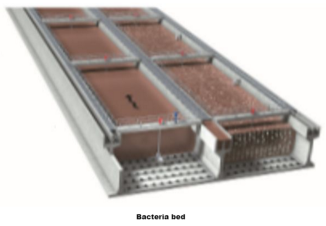

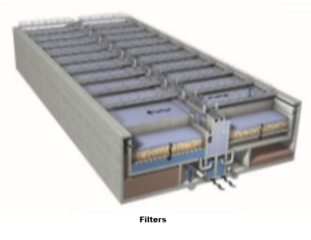

5. Filtration stage

Here is the final step of cleaning the waste water, using a fine sand filter to filter fine sludge and suspended matter.

Filters are periodically backwashed with air and water. The resulting sludge is pumped back to the mechanical treatment stage.

Depending on the water quality, iron sulfate can be added again to further reduce the phosphate content.

Finally, the purified water flows into the Limmat River through three inlets.

( 2 ) Sludge treatment (secondary digestion + incineration)

At Wade Holdsley, sludge from the sewage treatment process is nitrified before being sent to a sludge incineration plant as follows:

Primary nitrification process

The sludge flowing out from the primary settling tank is concentrated and then enters the primary nitrification unit. Here, the continuous incoming sewage and circulation pumps ensure that the sludge is constantly mixed and fermented.

Fresh sludge is heated through heat exchangers to about 38°C, where microorganisms ferment for about three weeks, breaking down organic matter and producing methane gas, carbon dioxide and water.

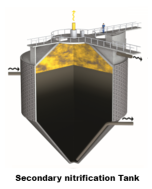

Secondary nitrification process

The secondary nitrification mainly serves for the fermentation of the rest of the decomposed organic matter. Here, the sludge continues to thicken without mixing.

The nitrification water enters the sludge dehydration unit together with the sludge concentrate. Add flocculants and dewater the liquid nitrified sludge with a centrifuge (moisture content drops from 97% to 70%).

The thickened sludge (30% dry matter) produced in the process is sent via a screw conveyor to a sludge recovery plant where it is recycled. The nitrified water will be returned to the biofilter after denitrification.

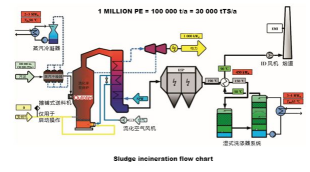

Sludge Recycling Plant

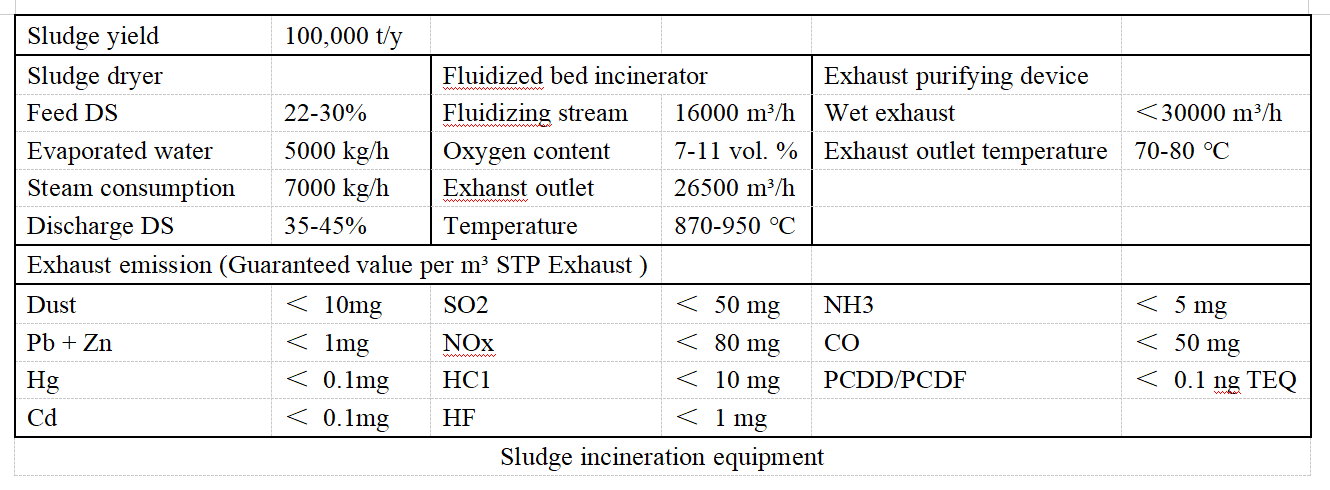

The sludge recovery plant in Wade Holzli is the largest thermal sludge treatment facility in Switzerland, capable of recycling sludge from more than 70 surrounding sewage treatment plants, amounting to 100,000 tons per year (corresponding to a dry matter content of about 30,000 tons/year).

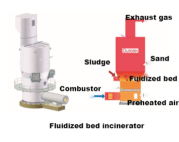

The plant itself consists of a sludge receiving hall, a fluidized bed combustion plant, and a flue gas cleaning system.

The dewatered sludge is mixed and transported to the dryer. After partial steam drying, the sludge is sent to an Outotec fluidized bed (FB) incinerator.

The water evaporated from the dryer is condensed in a steam condensing unit and the recovered heat is used for heating the city district of Zurich.

The hot flue gas from the incinerator is used to generate electricity in conjunction with a thermal power plant and to pre-dry sludge. The cooled flue gas enters the electrostatic precipitator, where more than 99% of the ash can be separated.

After dust removal, use spray drying system, adsorption reactor, bag filter and other devices to purify the flue gas.

The whole sludge disposal process can reduce the sludge disposal cost by nearly 50%.

( 3 ) Summary

In general, although Switzerland has a somewhat negative attitude in the fight against the epidemic, it still maintains a rigorous and positive attitude in terms of sewage treatment.

Every year, staff at the Wade Hordsley Sewage Works continue to monitor the 1,000-kilometre network of sewers, using underground cameras to inspect the structure and provide a 24-hour service to unclog the sewers.

Zurich will invest more than 40 million Swiss francs (about 300 million yuan) per year in the maintenance of sewer pipes alone.

Of course, Wade Hordsley Sewage Plant is a non-profit unit, and the profits generated during the process will be used for research and improvement of technical equipment.

10 years ago, Zurich tried to privatize the sewage treatment plant by learning from London, but "the result was disastrous". Only the non-profit sector can do its best to protect the sewer network of more than 1,000 kilometers.

It can be seen that the pursue of large-scale sewage treatment plants is not all technological advancement, but more attention to equipment operation and stability maintenance technology.

Special statement:

1. The article is reproduced on Beidu Environmental Protection Network;

2. We publish the article on the company website for use. If it violates the media or personal intellectual property rights, please contact us in time and delete it immediately.

08-31

202507-31

202506-30

202505-31

202505-15

2025