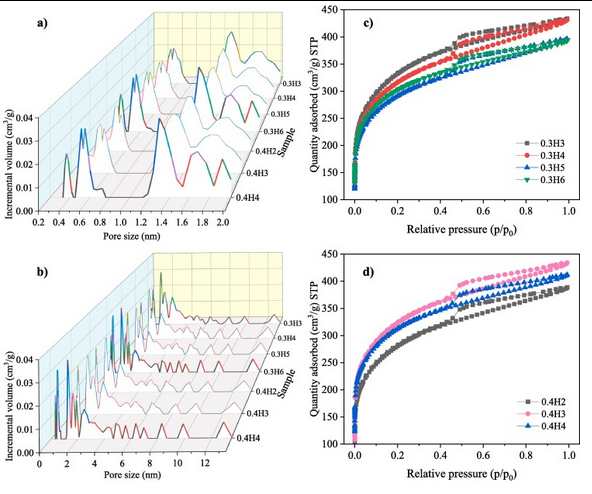

In this study, microwave-assisted phosphoric acid (H3PO4) activation was used to efficiently prepare activated carbons (ACs) with hierarchical porous structures within 2 minutes, showing excellent carbon dioxide (CO2) and methylene blue (MB) adsorption performance. This method uses agricultural waste as carbon precursors, and enhances the microwave absorption capacity of biomass by regulating dielectric properties. A single-step process can obtain activated carbon with a specific surface area of more than 1000 m2g-1 (energy consumption is only 2.4 GJ ton-1), successfully solving the environmental and economic cost problems faced by traditional activated carbon preparation. Among them, the 0.4H4 sample has a specific surface area of 1145 m2g-1 and abundant ultra-micropores (<0.7 nm). The CO2 adsorption capacity at 0℃ and 25℃ is 4.1 and 2.8 mmolg-1 respectively, and the CO2/N2 selectivity is >38. The adsorption equilibrium can be reached within 5 minutes, and the high-efficiency regeneration capacity is maintained after 20 cycles of adsorption and desorption. The 0.3H3 sample forms a large mesoporous structure of 1217 m2g-1 after 3 minutes of treatment, and the maximum adsorption capacity for MB is 281 mgg-1. Its adsorption mechanism involves mesoporous diffusion, electrostatic action, hydrogen bonding and π-π interaction between activated carbon and MB acidic groups. The experimental data is most consistent with the Freundlich model. The study confirmed that microwave technology can greatly shorten the processing time and convert waste into activated carbon with micro-mesoporous synergistic structure. Its comprehensive performance is better than that of traditional process products, and it has broad application prospects in the fields of post-combustion CO2 capture and printing and dyeing wastewater treatment.

Preparation

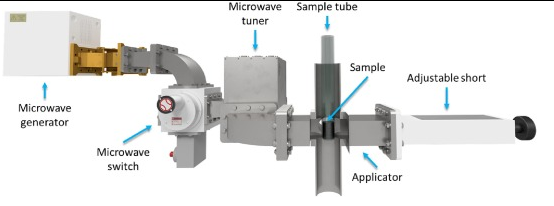

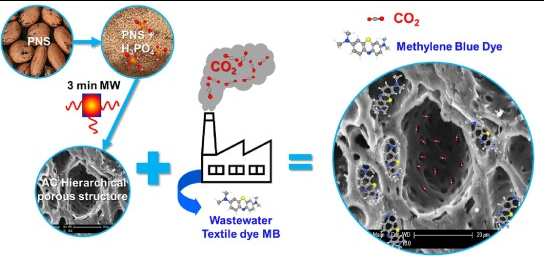

In this study, pecan shell-based activated carbons (ACs) were prepared by a one-step microwave pyrolysis-activation method. The specific steps are as follows: Pecan shell powder (PNS) with a particle size of about 1 mm was impregnated with phosphoric acid (H3PO4) in a mass ratio of 1:1 and placed in a specially designed rectangular single-mode microwave reactor. The reaction system is equipped with a quartz sample tube and a microwave leakage-proof metal sleeve (inner diameter 40 mm, length 110 mm, microwave attenuation>70 dB), connected to a 2.45 GHz, 2 kW microwave generator (Sairem®) through a WR430 aluminum waveguide, and an automatic tuner (S-TEAM STHD v1.5) was used to optimize power transmission (power absorption rate>75%). The entire preparation process was carried out under the protection of 5 L/min nitrogen. The schematic diagram of the experimental device is shown in Figure 1

Diagram

Figure 1: Schematic diagram of the microwave setup used to prepare AB samples

Figure 2: Schematic diagram of the preparation method of multi-level porous activated carbon and its application in CO2 and dye removal

Figure 3: N2 adsorption-desorption isotherms (c & d) and pore size distribution (a & b) of AC prepared in this study at -196 °C from the combination of N2 (-196 °C) and CO2 (0 °C)

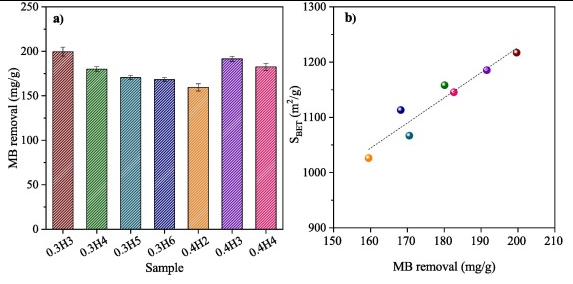

Figure 4: Comparison of MB removal from water using all ACs prepared in this study (a) and correlation with surface area (b)

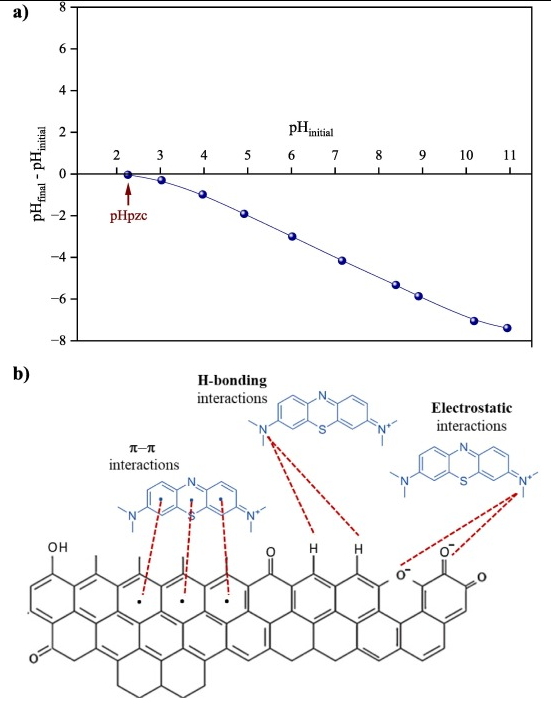

Figure 5: Changes in solution pH of 0.3 H3 carbohydrate suspension with initial solution pH (a) and possible adsorption mechanism of MB on 0.3 H3 activated carbon (b)

Conclusion

This study proposed an innovative microwave-assisted phosphoric acid (H3PO4) activation one-step method, which can quickly prepare activated carbon with hierarchical porous structure in a very short time (less than 3 minutes at the fastest). The prepared activated carbon shows dual application potential in the fields of post-combustion CO2 capture and printing and dyeing wastewater treatment by precisely controlling the pore structure characteristics: the large mesoporous structure significantly promotes the rapid diffusion and efficient removal of methylene blue (MB) dye, while the ultra-microporous structure gives the material excellent CO2 adsorption performance (including high adsorption capacity, CO2/N2 selectivity, fast kinetics and easy regeneration). Comparative studies with traditional preparation processes have confirmed that this microwave pyrolysis one-step method has significant advantages in converting waste into activated carbon with adjustable microporous-mesoporous structure. This technology not only provides a new paradigm for the preparation of porous materials that is sustainable, fast and efficient, but can also be extended to other industrial applications. Subsequent research will carry out pilot-scale production to promote the practical application of this material in industrial scenarios such as energy storage and hydrogen production.

If you think this information infringes upon your legitimate rights and interests, please send relevant qualification certificates and requirements to info@v-cheersfilters.com, and the website staff will respond as soon as possible!

08-31

202507-31

202506-30

202505-31

202505-15

2025