No.1 Method: Physical treatment

No.2 Equipment: regulating tank, grid, screen, sand settling tank, sedimentation tank, grease trap and other equipments.

1.Regulating pond

(1)In order to ensure the normal operation of subsequent treatment structures or equipment, it is necessary to adjust the amount and quality of sewage.

(2)Acidic sewage and alkaline sewage can be mixed in the regulating tank to achieve the purpose of neutralization.

(3)Short-term discharge of high temperature sewage can also be adjusted to balance the water temperature.

2.Grid

(1)Grid is a metal frame made of a set of parallel metal bars that are positioned diagrammed over the channel through which waste water flows or at the inlet of a pumping station's sump, to trap large blocks of suspended or floating solid pollutants that may clog the drainage pipes of pumps and settling tanks. The trapping effect depends on the gap width and the nature of the water.

(2)Classification

a.Planes and surfaces

b.Coarse grid (50~100mm), medium grid (10~40mm), fine grid (3~10mm)

c.Manual-clear grid, mechanical-clear grid.

(3)Application: Rotary grid decontamination machine Working principle: The rotary grid decontamination machine is assembled into a set of rotary grille chains by a unique rake tooth factory. Driven by the motor reducer, the harrow tooth chain moves in the direction of reverse water flow.

When the rake tooth chain runs to the upper part of the equipment, due to the guidance of the groove wheel and the curved rail, the relative self-cleaning motion is generated between each group of rake teeth, and most of the solid material falls by gravity. The other part relies on the reverse movement of the cleaner to clean up the debris stuck on the rake teeth.

According to the direction of water flow, the rake tooth chain is similar to the grating, and the rake tooth gap assembled on the rake tooth chain shaft can be selected according to the service conditions. When the rake teeth separate the solid suspension in the fluid, it can ensure the smooth flow of water. The whole working process is continuous, can also be intermittent.

3.Grit chamber

(1)Effects

Separate dense inorganic particles from sewage, protect pumps and pipes from wear, reduce the volume of sludge treatment structures, improve the content of organic components of sludge, and improve the value of sludge as fertilizer.

(2)Types

a.Horizontal flow (gravity) sand basin

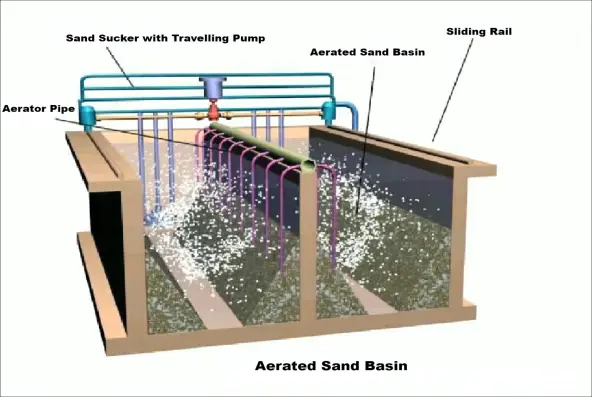

b.Aerated sand basin

Tips: The purpose of burst gas is to get enough dissolved oxygen for the water.

4.Sedimentation tank

(1)Sedimentation tank is a treatment structure that uses gravity sedimentation to remove suspended particles that are denser than water from water.

(2)Structure: water area, sedimentation area, sludge area, buffer area and water discharge area.

a.Inlet area and outlet area: make the water flow through the sedimentation tank evenly, avoid the short flow and reduce the adverse effect of turbulence on the precipitation of cattle, and reduce the dead water area to improve the capacity utilization of the sedimentation tank.

b.The sedimentation area is also called the clarification area, that is, the working area of the sedimentation tank: the area where the precipitation particles are separated from the wastewater.

c.Sludge area: the area where sludge is stored, concentrated and discharged.

d.Buffer area: It is the water layer area that separates the precipitation area and the sludge area to ensure that the precipitated particles do not float again due to the agitation of the water flow.

(3)The difference between Sedimentation tank and Grit chamber

a.A Grit chamber is generally a mud-water separation facility located in front of the biochemical structure of a sewage treatment plant. Most of the separated precipitating materials are sand with large particles, large proportion of precipitating materials, high inorganic composition and low water content. Sewage is inevitably mixed with mud and sand in the process of migration, flow and collection. If the sand in the sewage is not settled and separated in advance, it will affect the operation of the subsequent treatment equipment. The most important thing is to wear the pump, block the pipe network, interfere with or even destroy the biochemical treatment process.

b.Sedimentation tank is generally a structure for sludge and water separation before or after biochemistry, mostly for separating finer particles of sludge. Before the biochemical is called the primary sedimentation tank, the precipitated sludge is called more inorganic, and the sludge moisture content is lower than that of the secondary sedimentation tank. The sedimentation tank located after the biochemical process is generally called the secondary sedimentation tank, which is mostly organic sludge, and the sludge moisture content is higher.

(4)Principl of Sedimentation tank

The sedimentation tank is to purify water by using the principle that the downward sedimentation rate of the suspended impurity particles in the water flow is greater than the downward flow rate of the water flow, or the downward sedimentation time is less than the time of the water flow out of the sedimentation tank.

(5)Several general sedimentation tank types

a.Horizontal sedimentation tank

b.Vertical sedimentation tank

c.Amplitude flow sedimentation tank

d.Oblique flow sedimentation tank

No.3 Target pollutants: suspended solids in wastewater, oil slicks, initial pH adjustment.

No.4 Effect: Reduce the degree of waste water decay.

No.5 After primary treatment, waste water generally fails to meet discharge standards(BOD removal rate is only 25% to 40%). Therefore, it is usually the pretreatment stage to reduce the load of subsequent processing processes and improve the treatment effect.

If you think this information infringes upon your legitimate rights and interests, please send relevant qualification certificates and requirements to info@v-cheersfilters.com, and the website staff will respond as soon as possible!

08-31

202507-31

202506-30

202505-31

202505-15

2025