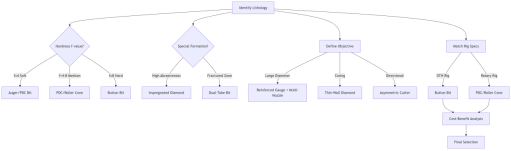

Here is the the drill bit selection guide, maintaining technical accuracy and industry terminology:

Rock Type | Recommended Bit | Breakage Mechanism | Application Case |

Soft Soil/Clay | Auger Bit | Shearing & Peeling | Foundation Piles (8-12 m/h ROP) |

Medium Hard (f=4-8) | PDC Bit | Polycrystalline Diamond Compact Shear | Shale Gas Well (Life >150 hrs) |

Hard Rock (f≥8) | Button Bit (DTH Hammer) | Impact Crushing | Granite Blast Holes (>20,000 J) |

Highly Abrasive Quartzite | Impregnated Diamond Bit | Diamond Grit Grinding | Gold Exploration (0.5 m/h ROP) |

Fractured Formation | Dual-Tube Bit + Casing System | Outer Casing Stabilization | Gravel Layer Anchor Holes (>90% Success) |

Notes:

l Protodyakonov Scale (f-value): Sandstone f=4-6, Granite f=12-18

l Cerchar Abrasivity Index (CAI): CAI>5 = Highly abrasive (e.g., Quartzite CAI=7)

Parameter | Bit Design Strategy | Example |

Large Diameter (>200mm) | Multi-Nozzle Jetting + Reinforced Gauge | Dam Grouting Holes (φ250mm, 60hr life) |

Deep Hole (>500m) | Precision Flow Path + Vibration Damping | Oil PDC Bit (>150°C rating) |

Directional/Horizontal | Asymmetric Cutters + High Build Rate | Shale Gas Well (8°/30m DLS) |

Coring | Thin-Wall Diamond Bit (ID/OD≥0.7) | Geological Survey (>95% Core Recovery) |

Rig Type | Compatible Bits | Key Constraints |

DTH Rig | Button Bit | Hammer-Adapted Ø (90-180mm) |

Top Hammer Rig | Cross-Type Carbide Bit | Max Impact Energy (≤500 J/blow) |

Rotary Drilling Rig | Bucket Tooth/Pick Bit | Torque Limit (<300 kN·m) |

Rotary Table Rig | PDC/Roller Cone Bit | WOB Requirement (≥80 kN) |

Mismatch | Consequence | Solution |

PDC Bit in Granite | Cutter Breakage (<5hr life) | Switch to Button Bit (>50hr life) |

Auger in Flowing Sand | Borehole Collapse (<50% success) | Use Dual-Tube + Foam Injection |

l Insufficient WOB: Roller cone requires 80 kN → 70% ROP drop if rig supplies 50 kN

l Excessive RPM: Impregnated bits max 300 rpm → Premature polishing at 800 rpm

Bit Type | Unit Price | Cost/m (USD) | Reason |

Low-Cost Alloy Bit | $110 | $16.5 | 6.7m life in hard rock |

Premium PDC Bit | $1,650 | $8.2 | 200m life in shale |

Conclusion: High-performance bits are more economical for hard rock/deep holes!

Application | Optimal Bit Specification | Key Parameters | Brand Reference |

Mine Blast Holes | Button Bit (Ø115mm) | 25,000 J impact, HRC60 inserts | Atlas Copco COP 64 |

Shale Gas Horizontal | 6-Blade PDC (Ø215.9mm) | 16mm cutters, >700°C stability | Baker Hughes Kymera™ |

Urban Anchoring | Dual-Tube Bit (Ø146/127mm) | Carbide-embedded outer tube | Zhejiang Chengzuan CZ-GP146 |

Geothermal Coring | Impregnated Diamond (Ø98mm) | 40-mesh diamond, HRC35 matrix | Christensen CTD-98 |

Solar Pile Foundation | Auger (Ø300mm) | 250mm pitch, 20mm blade thickness | SANY SY-S300 |

1. Test Drilling Parameters

Bit Type | Initial Setup | Optimization Signal |

PDC Bit | 60 kN WOB, 120 rpm | Flaky cuttings → ↑WOB to 80 kN |

Button Bit | 20 Hz impact, 2 MPa air | ROP<1 m/h → ↑Air to 2.5 MPa |

Impregnated Bit | 200 rpm, 100 L/min flow | Sudden SPP spike → ↓rpm to 150 |

2. Wear Inspection Standard

l PDC Cutters: Replace if wear height >1.5mm or chipped

l Button Bit: Replace if insert wear >30% or broken

l Auger: Repair if blade edge wear >10mm

"Rock type first, defines the bit's birth;

Size and depth lock specs on earth;

Rig parameters must tightly match;

Test-drill tuning cuts cost at batch."

Scientific selection boosts ROP by 50% and reduces cost/m by 30%.

If you think this information infringes upon your legitimate rights and interests, please send relevant qualification certificates and requirements to info@v-cheersfilters.com, and the website staff will respond as soon as possible!

08-31

202507-31

202506-30

202505-31

202505-15

2025